Max. Static Load: 425 - 4,000 lbs (1890 - 17,793 N)

"Engineered to isolate vertical shocks and reduce transmission of structural noise through floors..."

LORD Machinery Mounts are specifically engineered to isolate vertical shocks and reduce transmission of structural noise through floors.

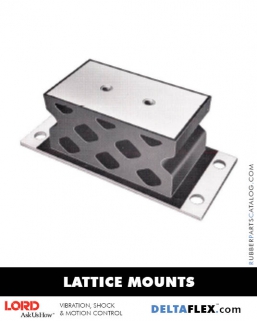

Lattice Mounts are designed to support medium to heavy equipment with disturbing frequencies as low as 360 cpm.

The lattice mount design provides a soft vertical spring rate combined with lateral stability.

Lattice Mounts are recommended for applications where disturbing frequencies are as low as 6 Hz.

Features and Benefits

- Heavy duty

- Low vertical spring rate

- May be floor mounted

- LORD quality

Typical applications

Lets Get Started!