Horsepower Rated: 4 hp to 135 hp at 2000 rpm

"For driveline Angular Misalignment,Torsional Vibration and Shock Protection nothing out performs LORD LCR Series Couplings..."

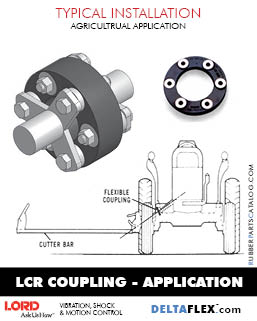

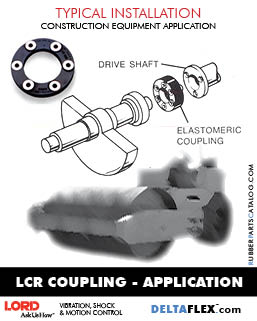

The LCR series has been developed to overcome numerous torsional problems associated with vehicular and industrial driveline systems. They increase equipment life by protecting against torsional vibration, shock and misalignment.

- Greater misalignment accommodation.

- Isolation of low frequency disturbances.

- Isolation of torsional shock.

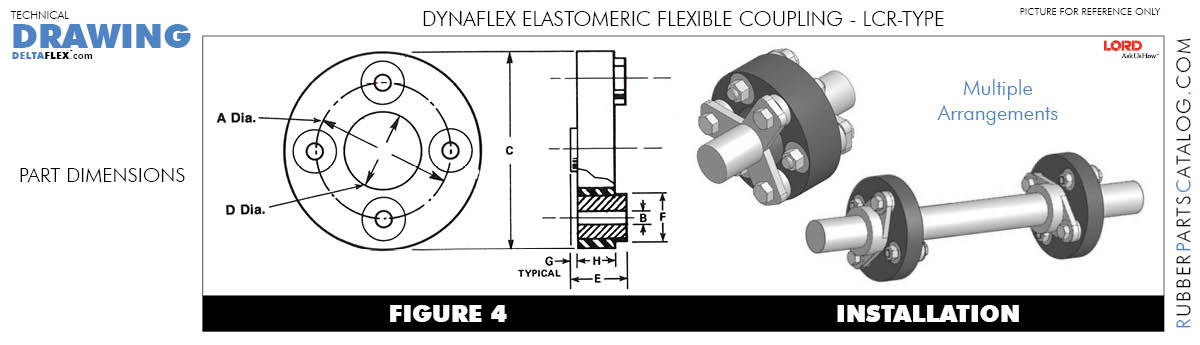

These ring-type, highly flexible elastomeric couplings for accessory drives are designed to eliminate lubrication and maintenance. They are easy to install.

LORD LCR Couplings reduce noise transmission and increase bearing and driveline life through greater misalignment accommodation, isolation of low frequency disturbances, and isolation of torsional shock.