Horsepower Rated: 10 hp to 600 hp at 2000 rpm

"Accommodate misalignment, cushion high torsional shock, and does not generate or transmit noise..."

LORD Dynaflex® Bushing-Type Couplings accommodate misalignment, cushion torsional shock, and do not generate or transmit noise. Since relative motion is taken in the elastomer rather than sliding metal surfaces, no lubricant is involved or ever required. Dirt and grit cannot effect the coupling bushings. The elastomer has been compounded to provide long service life.

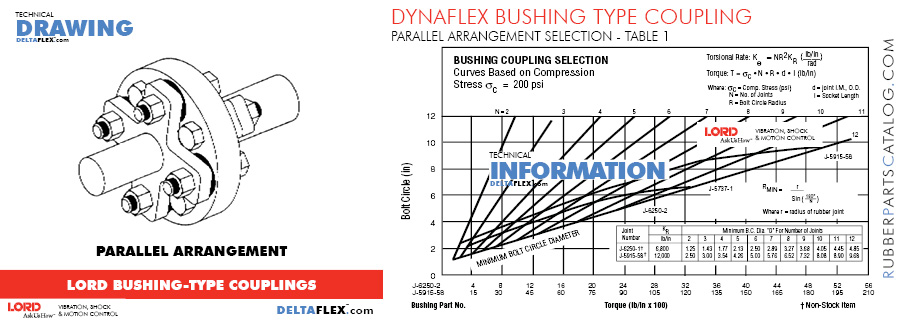

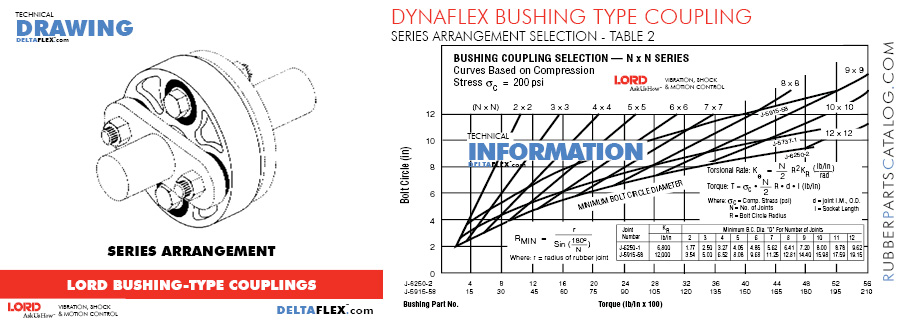

Specification, selection and dimension information provided in the catalog facilitate design of the coupling assembly. The bushings are standard parts, and the flanges can be supplied by the end user or by LORD as a special design.

Typical Applications

Driveline installations where multi-directional misalignment must be accommodated and torque loads are medium to high.